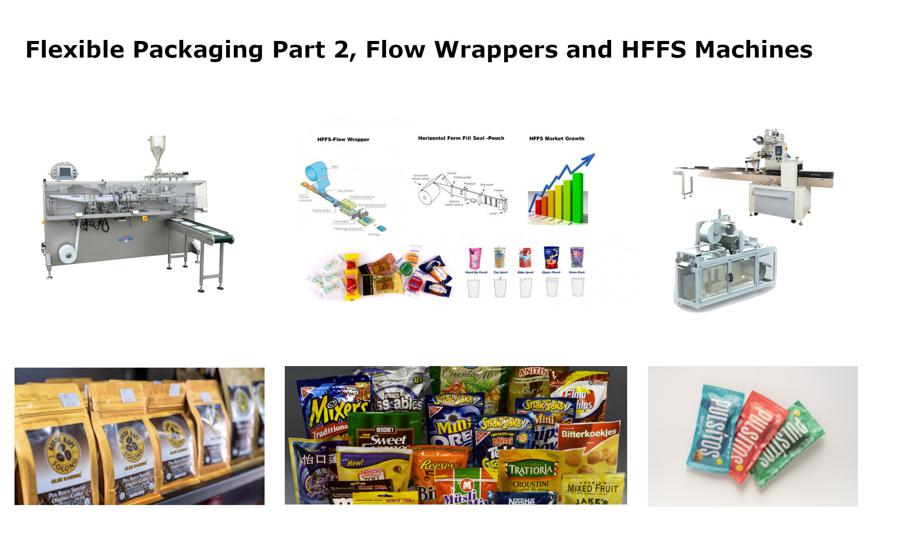

Flexible Packaging - Part 2 (Flow Wrappers, HFFS Machines; History and Current Market)

Food and beverage products can be packed in numerous ways. As flexible packaging materials have evolved, standard packaging technologies developed in the last 80 years have become specialised industries. Products can be automatically packed in flexible packaging materials via various FFS machines. Some of the main form fill seal machine categories in the market these days are VFFS (Vertical Form Fill Seal), HFFS (Horizontal Form Fill Seal), flow wrappers and thermoformers. Innovators are always trying to develop something new in their niche. On some occasions, the new products evolve into something different to what was originally intended. In 1949, Harold and Donald Bartelt developed a special machine to open, fill, close, and staple pre-made glued envelopes for electrical components. Almost immediately, this machine received lot of attention as one of the most innovative and labor-saving pieces of equipment in the packaging industry. The Bartlet brothers soon realised this and came up with patents for HFFS machine, developing quite a few of the early generation HFFS machines. The resulting public interest and inquiries prompted the Bartelts to pursue the continual development of packaging machinery. By the early 1960’s, their packaging machines to make, fill and close flexible film pouches were gaining popularity. The ‘Bartelt Intermittent Motion Packager’ soon became one of the industry’s benchmark HFFS machines of its time. Soon, other companies started to manufacture similar machines. Early movers included Kawashima, Volpack, Bossar, Fuji and Campbell Wrapper. Bartelt became part of ‘Klockner Bartelt’ and was eventually acquired by KHS. FFS machines primarily perform these three functions — 1. Form a bag OR make the primary product pack with flexible packaging material; 2. Fill it with products; 3. Seal it and discharge the finished package. HFFS machines generally cover two slightly different streams of machines — 1. HFFS pouch machines: the product is fed via gravity; 2. HFFS flow wrappers: the product is conveyed positively into the pack and therefore the position and speed can be controlled much more accurately. In HFFS machines, the flow of the film is horizontal, and various types of pouches, sachets and packs can be produced. Usually, the type of product, type of packaging and speed requirement determine the type of machine used. Leading suppliers of HFFS pouch type machines are concentrated in Barcelona, Spain, including Effytec, Mespack, Bossar and Acma-Volpack. Flow wrappers are used to wrap items such as candy bars, ice cream bars, brownies, cookies, muffins, and even medical devices and industrial parts. The leading flow wrapper machine manufacturers are scattered throughout the United States and parts of Europe, such as Bradman Lake, Campbell Wrapper Corporation, Bosch, Ulma Packaging, PFM Packaging Machinery, Imanpack, Ilapak and Ixapack. For some of the HFFS and flow wrapper machine manufacturers, the current situation is challenging, as they are struggling to successfully differentiate and market their products and solutions. Along with listening to customers and catering to their specific requirements, changes that would help grow the industry are... 1. Adapting machines to use recyclable and biodegradable laminate. Film wastage during product setup, leakers, and weak seals are common issues at most manufacturing sites. Machines that could run reliably even on suboptimal materials and self adjust with the change of materials could go a long way in improving productivity. 2. Machines that could produce shaped pouches, unique sachets, pouches with zippers and various other closures and spouts within a compact footprint and at a reasonable price point could further advance the trend towards flexible packaging. 3. For improving productivity, reliability and visibility, we have multiple tools and technologies. We must seriously consider the advantages of Industry 4.0, reliable connectivity with upstream and downstream machines, and integration with SCADA, ERP and CMMS systems. The current innovation stage of the HFFS machines and the flow wrappers’ life cycle may be debatable, but we would all like it to be in the rapid improvement stage. The leadership positions in this industry sector are changing, the products are becoming similar and cost and service deliverables are becoming the distinguishing factors. We at FoodBevHub think that one can remain attuned to the industry developments by becoming more involved, so we are doing our bit. Important considerations for when selecting HFFS machines; * Simpler is better! * Reliability and performance metrics; speed, wastages, uptime, quality of final packs, change over time, available options, capability to handle different materials, labour savings, skill availability and capability requirements to run and maintain the machine, ease of cleaning, flexibility in handling different sizes, and types of packs. * Quality and sanitary requirements; clean room, aseptic filling. * Total cost of ownership; initial cost, after sales service and support costs, repair and downtime costs, utility and consumable costs, spare parts and response time from manufacturer/supplier. * Integration with upstream and downstream equipment * Know your product and pack sizes, make sure that the machine is able to cater for all your products. * Type of final bag; pillow, gusseted, stand up pouches, zipper/resealable bags, bags with spouts, different shaped bags, available options and integration of additional options at a later time. * Multiple function machines, technology trends like ultrasonic sealing, better sealing technologies, advance servo technology, PackML compatibility, better diagnostic features, remote service support. * Design requirements; basis country OR company/industry standards requirement * References, brand name, interpersonal rapport. * Space constraint, lead time, cost constraints and other limitations. What do you think about where we are heading in this industry sector? Which HFFS machines have you used and how was your experience with them? We would love to hear your take on it.

Add comment Write your own Post

No comments here yet.

Please make your opinion count, let us know what you think...

More Posts

What is FoodBevHub?

FoodBevHub is a resource for information regarding various companies and contacts within Food and Beverage industry. There is 1000's of c .....Read more

Packaging Machines - Secondary Packaging Technologies, Basics Part 2

Cartoning Machines: Cartons are available in a variety of styles, shapes and sizes. They will generally be of board stock but may sometim .....Read more

Packaging Machines Basics, Wrapping Machines, Part 3

Wrapping machine Wrapping Machines wrap a flexible packaging material, (e.g. paper, film, aluminum), around a product or group of product .....Read more

Food Filling Machines, various filling technologies, part-4

Volumetric Fillers: Product is measured and dispensed by volume using a Volumetric Filler. The volumetric fillers can be of piston type, .....Read more

5S - Basics to improve Productivity

An organization that wants to improve productivity at the shop-floor and establish a lean culture need to first set up their environment usi .....Read more

Explore FoodBevHub

You can find, add or update any food and beverage industry related information here.

- Add Company

- Add Machines OR Products

- Add Contacts

- Add Post

- Add News

- Find Companies

- Find Machines/Products

- Find Posts

- Help Us Improve

Search Machines and Products

At FoodBevHub, our purpose is to improve productivity in Food and Beverage Industry.

You can list for FREE and sell Used machines for Food and Beverage Industry, second hand and new packaging machines, processing equipment etc.

Access information regarding Australian companies within Food and Beverage industry

OR

Create and post relevant content

If you want to contact us, please send an Email to info@foodbevhub.com.au